Intelligent Feeding

With the high-precision imported material level detection sensor from Germany, combined with the logic control of the PLC feeding system, intelligent feeding is realized. It can avoid the two working conditions of material blockage leading to shutdown and insufficient feeding, ensuring that the equipment can stably maintain the optimal performance output and the production output remains stable.

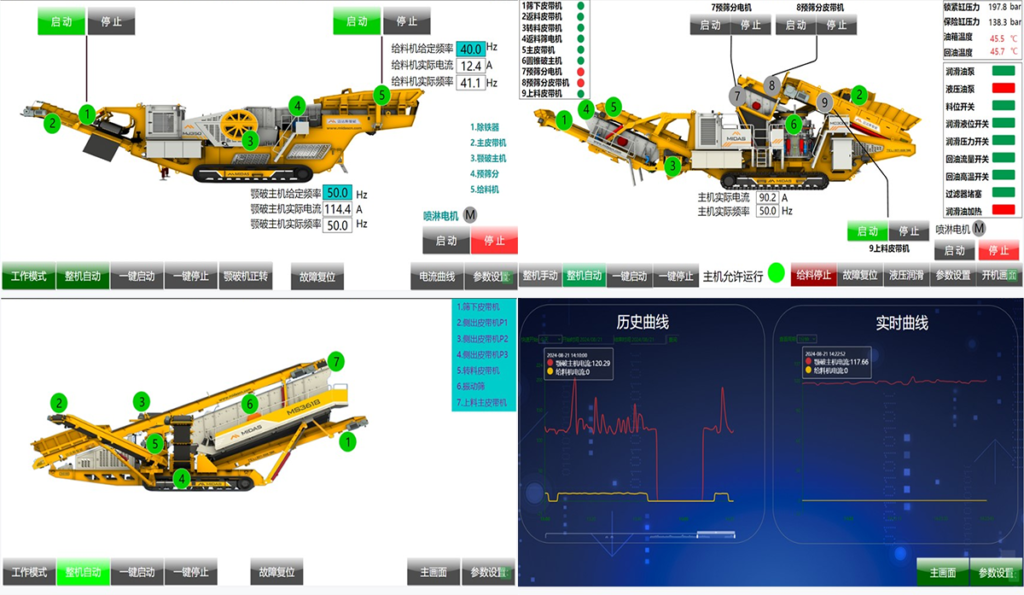

One-click Start And One-click Stop

With one-click start and one-click stop functions, and automatic fault diagnosis and display, it brings great convenience to customers.

Frequency Conversion Start And Touch Screen Operation

The main machine adopts frequency conversion start. The whole machine is equipped with a Siemens PLC controller, and it can be operated via a touch screen.

Dual-mode operation

Freely choose between the manual individual control mode and the automatic integrated control mode.

Intelligent interlock between single-machine modules

When a fault occurs during the operation of a single module, the system will automatically stop feeding and lock the feeding stop state to prevent the system from piling up materials and jamming, which may cause the equipment to stop and be damaged.

Intelligent interlock for multi-machine collaborative operation

When an abnormal situation occurs or there is excessive feeding in a single piece of equipment, it will send signals to upstream and downstream equipment to achieve automatic adjustment and monitoring functions. This enables the entire production process to always remain stable. The feeding control of the continuous feeding system can ensure that the crusher achieves its ideal production capacity.