Selecting the ideal mobile crusher plant is critical for maximizing ROI. This guide covers key factors from budget planning to material analysis, helping you make informed decisions tailored to your project needs.

Step 1: Define Your Budget & ROI Goals

Initial investment range

The initial investment in the crushing station may account for 30% – 50% of the total cost of the construction project. Making a reasonable planning budget can prevent subsequent disruptions in the capital chain and operational losses.

Small – scale projects (<50 TPH): $50,000 – $150,000 (Recommended model: OLJ – 150 Mobile Jaw Crusher)

Medium – scale projects (50 – 200 TPH): $150,000 – $500,000 (Recommended model: OLIS – 200 Impact Crusher + Screen)

Large – scale projects (>200 TPH): $500,000+ (Recommended modular solutions)

Hidden cost reminder

Transportation costs

International maritime transportation accounts for 5 – 10% of the equipment cost.

Tariffs

with an average of 12% in Southeast Asia

Spare parts inventory

annual cost is approximately $10,000

Calculate Your ROI

Estimated Annual Revenue: $0

Step 2: Calculate Required Production Capacity

Formulas and Cases

Formula:

Daily production capacity (TPH) = Total aggregate demand of the project (tons) / Effective working days

Case:

- Project requirement: 100,000 tons

- Construction period: 9 months (approximately 270 working days)

- Daily production capacity = 100,000 / 270 ≈ 370 TPH → Select 370 TPH – class equipment (such as OLI – 370 Mobile Impact Crusher)

Step 3:Analyze the material characteristics&site conditions

Material Testing Guide

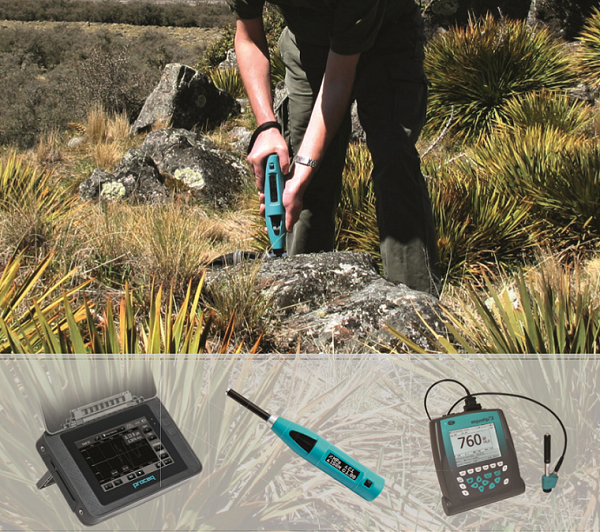

1. Hardness Test:

- Tool: Schmidt Hammer (used to quickly determine Mohs hardness on – site)

- Application of Results: If the hardness is greater than 6, select a cone crusher; if less than 6, select an impact crusher.

2. Mud Content Detection:

- Method: Take a 500 – gram sample, wash it with water, dry it and weigh it, then calculate the percentage of mud content.

- Suggestion: If the mud content is greater than 5%, a sand washing machine needs to be equipped.

Step 4:Match equipment with aggregate uses

Comparsion table

| Comparison table: | |||

| Usage of aggregates | Equipment type | Finished product requirements | Recommended Model |

| Concrete aggregates | Impact crusher | Multi-angled cubes with powder content<5% | OLI-200 Impact Crusher |

| Asphalt aggregates | Cone crusher | Flaky&elongated particles<10%, dry&mud-free | OLC-300 Cone Crusher |

| Railway ballast | Jaw crusher+impact crusher | Uniform particles sized between 50-70mm | OLJI-500 Jaw + Impact |

Comparison diagram of particle shapes produced by different crushers

Step 5:Optimize Long - Term Operating Costs

Cost comparison

- Energy consumption cost:

Jaw crusher: $1.5 – 2.5 per ton vs Cone crusher: $2.5 – 4.0 per ton

- Wear – resistant parts lifespan:

High – manganese steel jaw plate: 6 – 12 months → Replacement cost: $3,000 per time

Ceramic composite plate: 18 – 24 months → Replacement cost: $5,000 per time