The commercial concrete sector pertains to the industry that centers around the production and marketing of concrete. Premixed concrete, which is fabricated by a concrete mixing station following a specific proportion and procedure, boasts stable quality and dependable strength. It finds extensive application in construction projects, infrastructure development, and roadway works.

OLEEK Leads the Production of High-quality Commercial Concrete Solutions

The commercial concrete business represents a remarkably specialized and technologically converged domain, covering the generation, delivery, and employment of concrete within diverse construction and engineering undertakings. Notably, concrete must exhibit varying traits and adhere to distinct quality benchmarks to cater to the requirements of different engineering categories.

Allow me to present to you the machinery employed throughout the production and utilization of commercial concrete. This will assist you in gaining a more comprehensive understanding of the operational pattern of the entire industry and offer precise directions for your projects.

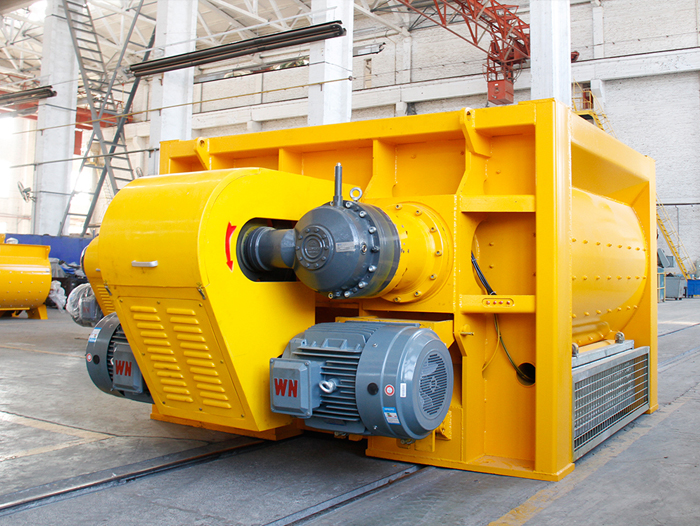

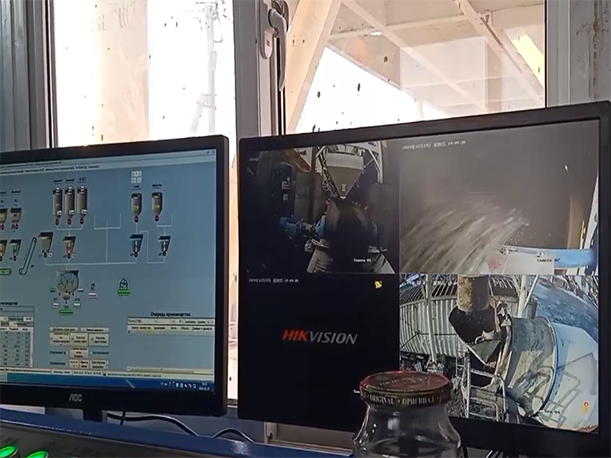

Concrete mixing plants: OLEEK offers concrete mixing plants in multiple models, providing different configurations and production capacity options, which can be used for large-scale production of high-quality concrete. OLEEK’s concrete mixing plants adopt high-performance mixing units, such as the JS series twin-shaft compulsory mixers, ensuring that the concrete is mixed quickly and evenly. Equipped with advanced electronic control systems, they can achieve fully automatic control, making the production process more stable and reliable.

Concrete mixer trucks: Concrete mixer trucks transport the concrete produced by concrete mixing plants to construction sites. The partners of OLEEK can provide concrete mixer trucks with different capacities to meet the needs of projects of different scales. Equipped with high-efficiency mixing drums, both the mixing drums and blades are made of high-strength steel, which are wear-resistant, can extend the service life and reduce maintenance costs.

Concrete trailer pumps: Used to transport concrete from mixer trucks to specific construction points, especially suitable for long-distance or elevated construction sites.

Boom pumps: Transport concrete to construction sites through retractable booms, and are applicable to taller and more complex construction environments.

Environmentally friendly mixing plant

The environmentally friendly mixing plants of OLEEK are designed to minimize the impact on the environment during the production process while maintaining high-efficiency and high-quality concrete production by integrating a series of advanced environmental protection technologies and facilities.

Reduce environmental pollution: The environmentally friendly mixing plants of OLEEK adopt systems such as dust removal systems and wastewater recycling systems to effectively reduce dust and noise pollution generated during the concrete production process as well as air and water pollution around the construction site.

Improve production efficiency and quality: Through automated control systems, precise batching and metering, and efficient mixing technologies, the continuity of concrete production and the consistency of each batch of concrete are ensured.

Energy conservation and emission reduction: The environmentally friendly concrete mixing plants of OLEEK have achieved lower energy consumption and higher raw material utilization efficiency by optimizing equipment configurations and production processes.

Raw materials for producing concrete

Concrete is composed of main materials: aggregates, powders, water and additives.

- Aggregates: Aggregates, such as gravel, sand or crushed stone, provide volumetric stability and mechanical properties for concrete, ensuring that it can withstand load and durability requirements.

- Powders: These include cement and fly ash, which are used as binders in concrete to provide strength and durability.

- Water: Water is an important component of concrete. The quality and quantity of water have a significant impact on the properties of the final concrete.

- Additives: Additives are used to modify the characteristics of concrete.

These four main components—aggregates, powders, water and additives—play a crucial role in determining the properties of concrete and its suitability for various applications.

Characteristics and advantages of ready-mixed concrete

Stable quality

Concrete batching plants produce commercial concrete with strict proportions and processes. This ensures controllable quality, stability and reliability. Scientific and rational production methods contribute to its excellent strength and durability.

Efficient production

Modern concrete batching plants are equipped with advanced equipment and automated control systems. Standardized production processes ensure efficiency throughout the production process.

Environmental protection and energy saving

During the production process of commercial concrete, the discharge of waste and pollutants can be managed efficiently, fulfilling the environmental protection stipulations. By means of scientific and proper proportioning along with the application of admixtures, it becomes possible to cut down the quantity of cement utilized. This not only decreases the energy consumption but also accomplishes the goals of energy conservation and emission reduction.

Wide range of applications

With remarkable performance, advanced production technology and the feature of sustainability, commercial concrete is broadly utilized and occupies a significant position in multiple fields.

OLEEK's Help In The Commercial Concrete Industry

For customers engaged in the commercial concrete industry, Aimix can provide a series of efficient and reliable construction machinery and equipment and comprehensive service support to meet their needs in the production, transportation and pouring of concrete.

Customized Solutions

OLEEK can put forward a series of construction machinery and equipment that boast high efficiency and reliability, and also provide comprehensive service support. The whole package is aimed at fulfilling their necessities during the production, transfer, and pouring of concrete.

Optimize Production Process

OLEEK not only provides equipment, but also offers professional consulting and guidance services to help customers optimize production processes and improve production efficiency and product quality. Through the analysis and improvement of production links, the entire production process becomes smoother and resource waste is reduced.

Comprehensive After-sales Service

OLEEK makes it its mission to offer comprehensive after-sales service aids. It features equipment installation arrangements, the meticulous commissioning phase, training sessions for operational know-how and proficient technical consultations. With such services in place, customers can effortlessly start production subsequent to the equipment purchase.

Technological innovation and upgrading

OLEEK persists in pushing forward technological innovation and upgrading its products. Its objective is to offer commercial concrete machinery that is not only more efficient and environmentally conscious but also highly user-friendly. In this way, customers are empowered to relish the state-of-the-art technology within the sector, thereby enhancing their production efficiency as well as the quality of their products.

Environmental Commitment

In view of the influence exerted by the construction industry on the environment, OLEEK makes it its mission to develop equipment with low emissions and high energy efficiency, thus assisting customers in attaining their sustainable development objectives.

You can contact us via message or call our sales hotline