Concrete Batching Plant is a large-scale automated concrete mixing equipment. Controlled by an intelligent system, it scientifically mixes cement, aggregates, water, and other additives in proportion to produce homogeneous concrete. Its core functions include precise weighing (controlled by sensors and computers) and efficient mixing (using forced or self-loading mixers). It is mainly used in engineering projects that have a large demand for concrete and cannot carry out on-site mixing.

Main Components

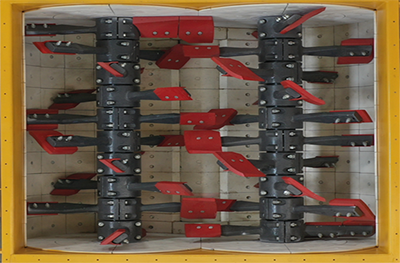

Mixing system: According to the mixing method, it is divided into forced mixers and self-falling mixers. Forced mixers are classified into main shaft planetary mixers, single horizontal shaft mixers, and double horizontal shaft mixers. Among them, double horizontal shaft forced mixers have better comprehensive performance and are more commonly used.

Weighing system: High-precision sensors ensure the precise proportioning of cement, aggregates, water, and additives. Equipment with a production capacity of over 50 cubic meters per hour mostly adopts compartment weighing.

Belt conveying (high efficiency, low failure rate) or hopper lifting (space-saving)

Control system: It is fully automated by computer. The background system conducts scientific proportioning and supports automatic error correction.

Main Types At Present