Crawler mobile crushing station

Good product particle shape/ Ultra-strong impact resistance/high output, high cost performance/and environmentally friendly

3 main application scenarios of the crushing station

Mine development and tailings disposal

Mining operations

Front-end mining to increase revenue in large mines, flexible production increase and allocation in mobile mining, direct mining application in small and medium-sized mines, and tailings recovery in mine greening projects

Infrastructure Project Treatment and Reuse

Infrastructure projects

Used in cement stabilization stations, commercial concrete stations and asphalt stations, such as: road construction, bridge construction, hydropower engineering, building construction, etc.

Treatment and Utilization of Construction Solid Waste

Solid waste treatment and recycling

Solid waste management involves the collection, treatment and disposal of waste generated by human activities. Proper handling of solid waste is essential for environmental protection, public health and resource conservation. By reducing, recycling and reusing solid construction waste, we can minimize negative impacts on the environment and promote sustainable development. Technological innovation and policy development are key to improving efficiency and reducing solid waste generation, thereby creating a cleaner and healthier planet for future generations.

Mobile Crusher Plants With Different Model For Selection

According to the type of rocks to be crushed, their hardness, humidity, and other material characteristics, as well as the production requirements, select the appropriate model of the crushing station. We provide jaw crushing stations, cone crushing stations, impact crushing stations, etc., to meet the needs of various working conditions.

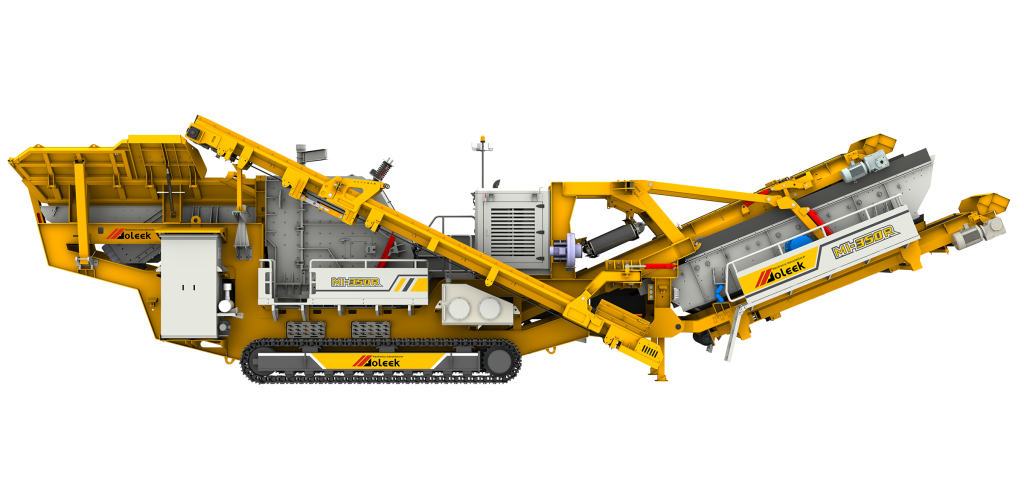

Impact Type Mobile Crusher Plants – Low Production Cost

OLEEK OI series of Crawler Mobile Impact Crushing Plants feature compact and efficient modules. Hydraulic assistance is applied in multiple aspects. A return material screening system is added, and there are also iron removal, wind separation and spraying devices.

It is suitable for the first and second crushing stages of medium and soft hardness materials, ore crushing in mines, construction waste recycling, production of construction aggregates, as well as highway/railway and road and bridge construction. The whole machine has stable performance, is convenient for relocation, and can produce good crushed particle shapes.

Feeding Size: ≤700mm

Capacity:

100-600T/H

Crusher Types: Impact

Finished Particle Size: 25-100mm

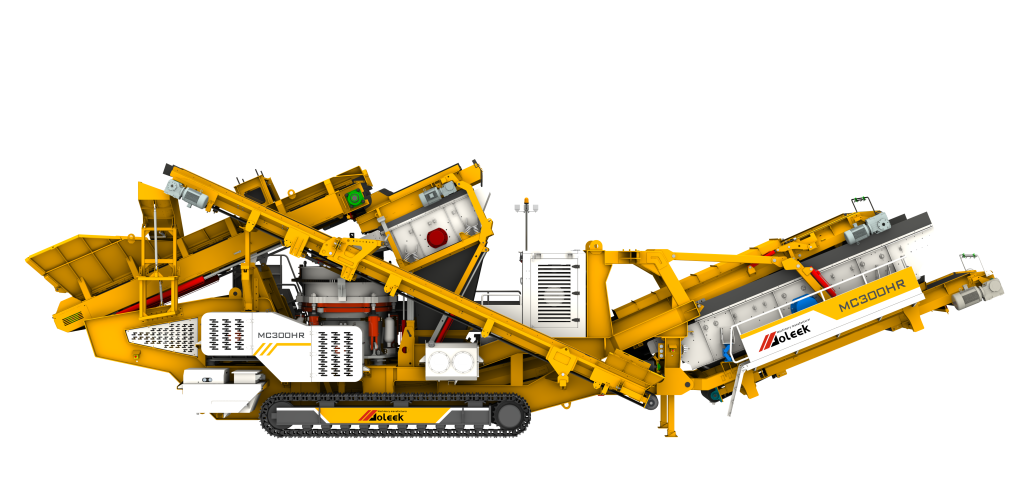

Cone-Type Mobile Crusher Plant – Secondary Or Tertiary Crushing

OLEEK OC series crawler mobile cone crusher adopts multi-cylinder cone to achieve laminated crushing, and is equipped with a large torque reduction feeder to ensure uniform feeding. It is suitable for the secondary and tertiary crushing of medium and high hardness materials, the crushing and sand making of highly wear-resistant stones (SiO2 content higher than 75%) such as river pebbles, granite, diabase in quarries, and the crushing of iron ore before ball milling in large ore dressing plants. The whole machine has a compact structure, easy relocation, large crushing output, small wear and high reliability.

Feeding Size: ≤300mm

Capacity:

150-500T/H

Crusher Types: Cone Crusher

Finished Particle Size: 0-45mm

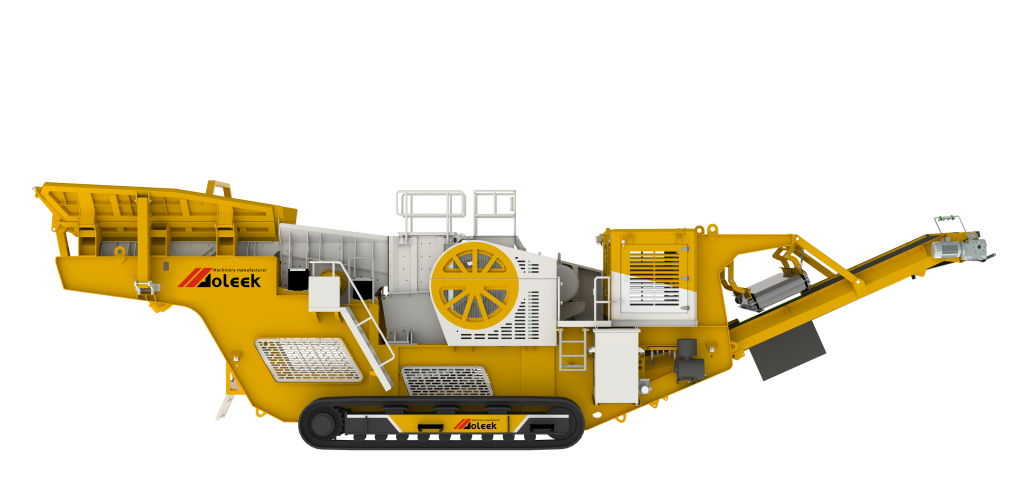

Jaw-Type Mobile Crusher Plant – Primary Crushing

OLEEK OJ series of Crawler Mobile Jaw Crushing Plants are equipped with the European version C series crushing main units, oversized folding hoppers, and an independent pre-screening system is added. There are also iron removal and spraying devices. They are mainly used for the primary crushing of medium and high hardness materials, ore crushing in mines, construction waste recycling, production of construction aggregates, highway/railway construction, and road and bridge construction, etc. It is convenient for relocation and has high crushing efficiency.

Feeding Size: ≤600mm

Capacity:

80-570T/H

Crusher Types: Jaw

Finished Particle Size: 40-200mm

What are the advantages of the OLEEK mobile crushing station?

We are determined to be the best. We have a dedicated research team and a production team, integrating professionalism and innovation into the products and services we provide. We aim to reduce customers’ investment and increase their returns. We break down and study every detail of the crushing station and upgrade them, so as to improve the overall performance and service life of the equipment.

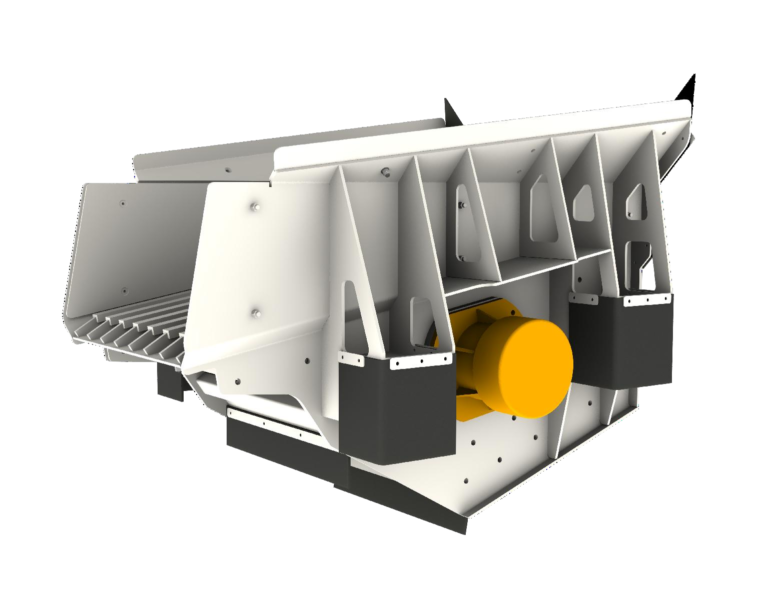

Hopper Module

Ultra-large hopper volume: The overall volume can reach up to 7 cubic meters, which is more than double the hopper volume of products from other manufacturers. It is specifically suitable for loading materials by excavators and loaders, ensuring that there is no material spillage and can meet the working condition requirements for loading large pieces of materials.

Wedge block fixation: The wedge blocks fix the tail and the material plates on both sides. It is more convenient to disassemble, and the connection is more secure, preventing potential safety hazards caused by vibrations during operation.

Feeder + Independent Pre-screening Module

Feeder: The connection seat of the vibration motor is processed with high precision and meets high standards. The connecting and fitting surface is more refined, the force distribution is more uniform, and it is durable. .

Independent Pre-screening: An independent pre-screening machine is used. The materials in the raw materials that are smaller than the finished products will be pre-screened by the grate bars and then enter the main belt conveyor (for finished products) or the side discharge belt conveyor (for fine dust materials). This effectively reduces the working load of the main crushing machine, which is equivalent to increasing the output. At the same time, it can provide sufficient crushing space for the main machine to crush large pieces of materials, reduce the wear of wearing parts caused by fine materials, improve efficiency, and lower the production cost. .

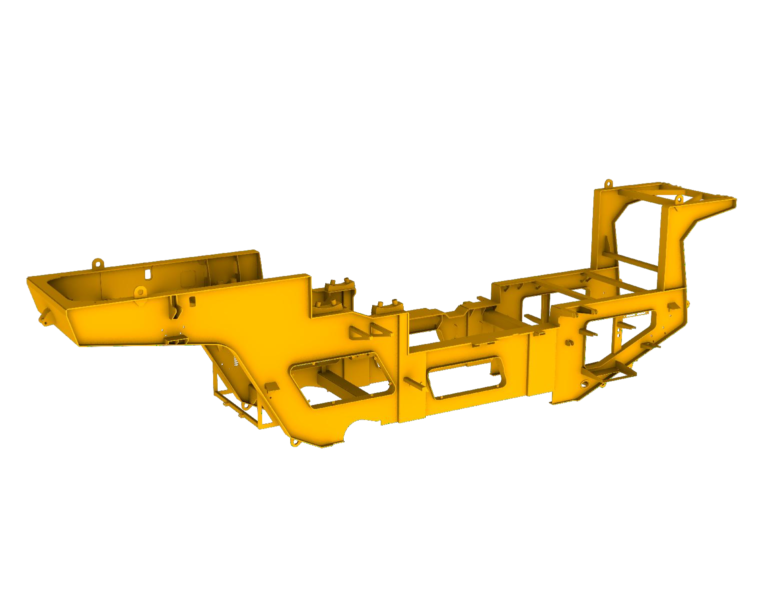

Frame Module

The new-generation reinforced steel frame adopts a full heavy-duty structural design, and materials with higher strength and better low-temperature performance are selected. The force-bearing area of the jaw crusher features a unique structural design, which is different from the single-web structural design of other manufacturers. Its stiffness and strength are greatly enhanced. It is specially designed to handle the heavy-duty and high-impact working conditions of the jaw crusher. The entire machine is more robust, stable, and has a longer service life!

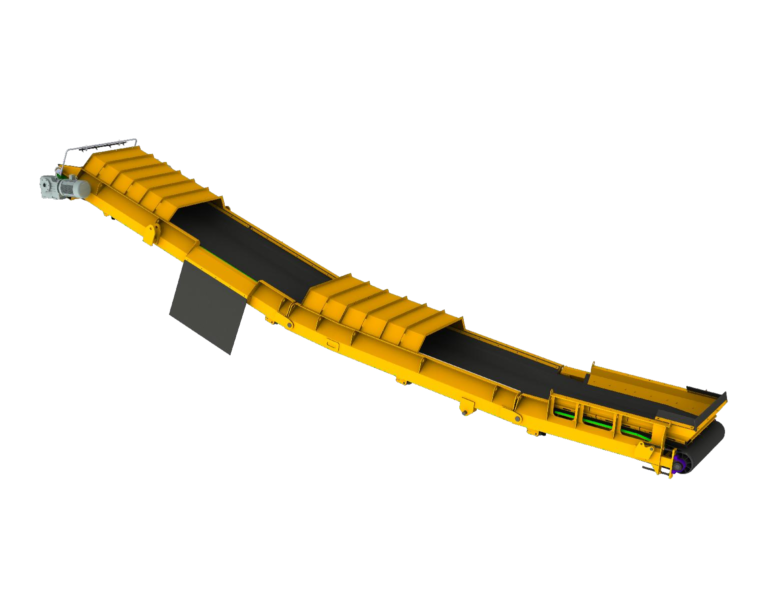

Frame Module

All belt conveyors are driven by motor reducers. The driving scheme has more advantages compared with the electric drum driving method. It has good heat dissipation performance.

The electric drum driving method has the problem of overweight head. Long-term shaking will cause stress deformation to the structural components of the main frame of the belt conveyor. When working under full load for a long time, it will generate heat. Since the drum has poor heat dissipation performance, it leads to a particularly high failure rate and a long maintenance and replacement cycle, which instead increases the indirect cost of shutdown.

The power reserve of the motor drive is larger than that of brands of the same industry. It has a large driving force and greatly extends the service life!

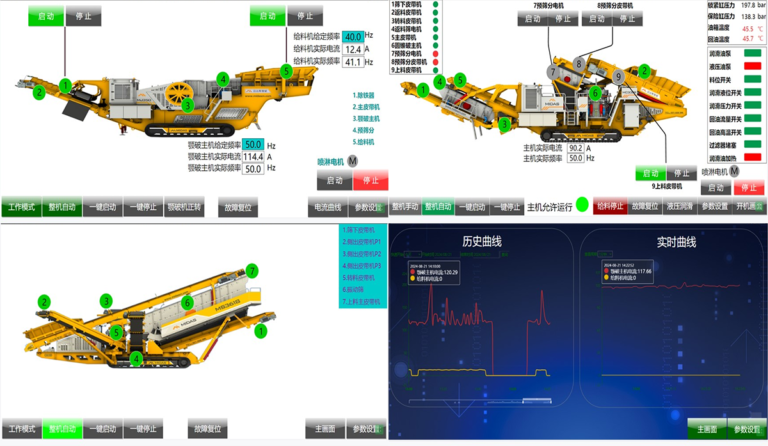

PLC intelligent control system

PLC electrical control operating system adopts Siemens brand PLC controllers and touch screens, which are simple and convenient to operate, reliable in quality, and stable in performance. The operation interface can display the working status of each module, system parameters, etc. in real time. For example: the actual working current and real-time frequency of the main crushing machine motor, the start interval time of each module, the working pressure of the hydraulic/lubrication system, etc.

What is the best rock crusher for rock?

Select an appropriate crushing station so that it can operate at full load, avoiding delays caused by equipment overload shutdown or insufficient production capacity. Reduce the waste of idling,Avoid energy waste caused by an overly large model or frequent start and stop when the processing capacity is insufficient, and improve the continuous operation ability. It has a stronger adaptability to materials, reduces the abnormal wear and tear of vulnerable parts such as hammers and liners, and saves the cost of spare parts.

The characteristics of the materials (hardness, humidity, size)

- Physical properties: Hardness (Mohs hardness classification), density (in loose/compacted state), humidity (whether pre-drying is required), abrasiveness (equipment is prone to wear when the quartz content is high), and mud content (affecting the screening efficiency).

- Feed specifications: Maximum particle size (determining the model of the primary crusher), particle size distribution (whether multi-stage crushing is required).

- Finished product requirements: Target particle size (such as 0-5mm aggregate), shape (select an impact crusher or a vertical shaft impact crusher if there is a high demand for a cubic shape), and the allowable range of impurities (whether an iron remover is needed, etc.).

Production requirements (production capacity, specifications of the discharged materials)

- Production capacity target: Daily average processing capacity (tons per hour), number of annual operating days (a durable model should be selected for high-frequency operation)

- Production ratio: When the materials are discharged, what is the proportion of stones with each diameter?

Site conditions (terrain, power supply situation)

- Site limitations: Frequency of movement (crawler type is required for daily site transfer, while tire type can be used if it is fixed for several months), terrain slope (anti-skid design is required for slopes greater than 15°), spatial layout (restrictions on the folded transportation size of the equipment).

- Power conditions: Stability of power supply (use diesel engines in areas with power shortages), voltage system (380V/440V should be adapted for overseas projects).

Environmental protection requirements (noise and dust control)

- Dust and noise control: For example, the mobile crushing station is equipped with an integrated dust removal system and a sound insulation cover, which makes it easier to meet the environmental protection requirements for the treatment of urban construction waste compared with traditional equipment.

- Emission reduction design: Adopt the process of energy-saving motors, which directly reduces carbon emissions.

Treatment and Utilization of Construction Solid Waste

Resource utilization of construction solid waste, processing and recycling of waste concrete blocks, processing and recycling of tunnel slag

Mine development and tailings disposal

Front-end mining to increase revenue in large mines, flexible production increase and allocation in mobile mining, direct mining application in small and medium-sized mines, and tailings recovery in mine greening projects

Infrastructure Project Treatment and Reuse

Used in cement stabilization stations, commercial concrete stations and asphalt stations, such as: road construction, bridge construction, hydropower engineering, building construction, etc.

REQUEST A QUOTE!

Customize your solution

- Please describe the type of project (for example, building houses, factories, roads, bridges, dams, airports, etc.)

- Please list the specific equipment or types (such as crushing stations, asphalt stations, batching stations, self-loading mixers, concrete pumps, etc.)

- Please tell us when your expected equipment or project is scheduled to start upgrading

- Please elaborate on your specific requirements or expectations (for example, project location, voltage, climate, etc.)

Our professional team of engineers will provide you with multi-to-one project guidance!

Business negotiation

Solution development

Manufacturing and commissioning

Operational production

Partners